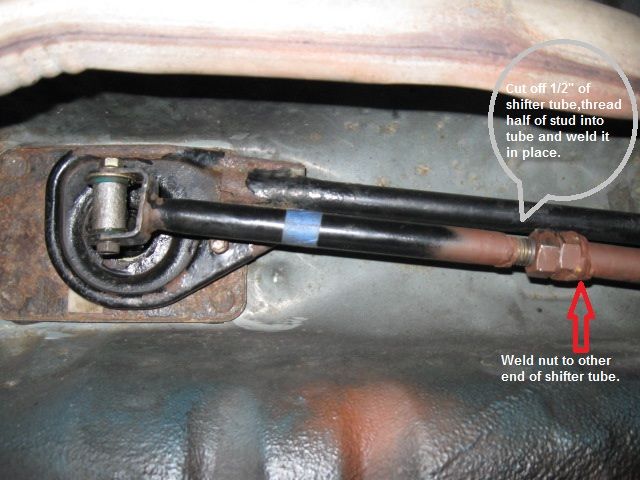

We had to modify the shift rods on the "Smurf car" when the "F" transaxle (1989 Tracer donor car) and we have some "grinding" when we shift into reverse. The clutch etc are all brand new, This leads me to believe that we do not have the shift forks in their proper position. We will have to cut the rods and change the angle of the front of the rod to the back of the rod. Does anyone have any suggestions on how we will be able to achieve this? Has anyone else had to modify their shift rods for a particular application>

cortezit

cortezit

Comment